Laser Cutting Machine Come Into Operation

As the development and expansion of the world's sheet metal manufacturing, China has gradually become the center of international processing and manufacturing, along with increase of foreign investment, the increasing demand in metal processing requires the great improvement of sheet metal fabrications.At the same time, there is also higher requirement comes for the process complexity.Even some parts require more than dozens of procedure,which require high accurancy and low tolerance.Under the fierce competition,our company use laser equipment in the industry and applies it to the manufacturing of various metal products.Because of its flexibility, high advantages, so as to provide our customers withmore quality, efficient service.

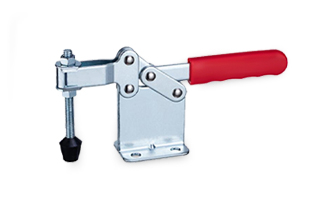

The laser equipment used by our company is a high-speed fiber laser cutting machine integrating plate and tube. The advantage is don’t need tooling,which save lots of tooling cost and raised therate of labor productivity

The main advantages are as follows:

1 Because of no contact processing, and the laser beam energy and moving speed can be adjusted, so it can finish a variety of processing;

2. It can be used to process different kinds of metals, especially materials with high hardness, high brittleness and high melting point.

3, no "tool" wear, no "cutting force" influence on the workpiece;

4, the processing of the workpiece thermal impact zone is small, the workpiece thermal deformation is small, the subsequent processing volume is small;

5. The workpiece in the sealed container can be stopped from all kinds of processing by transparent medium;

6, easy to guide, through focusing can complete the target transformation, easy to cooperate with the CNC system;

7. High level of initiative, can be completely closed processing, no pollution, low noise, greatly improved the task of operators;

The system itself is a set of computer system, can facilitate the arrangement, modification, suitable for characteristic processing, especially for some sheet metal parts with complex shape, large batch with small quantity, shot product life cycle. It is more convenient, fast and efficient, because it can be processed without tooling

9, the processing of large energy density, short impact time, small thermal impact zone, small thermal deformation, thermal stress, plus laser for non-mechanical contact processing, no mechanical stress effect on the workpiece, suitable for fine processing.

10, high energy density is enough to melt any metal, especially suitable for processing some workpiece with high hardness, high brittleness, high melting point

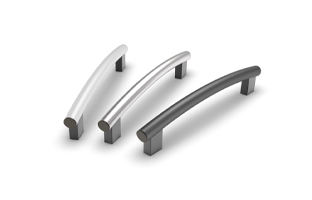

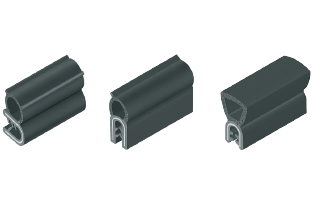

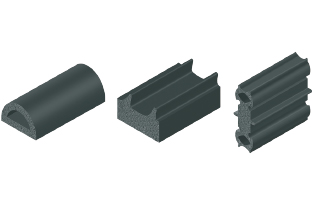

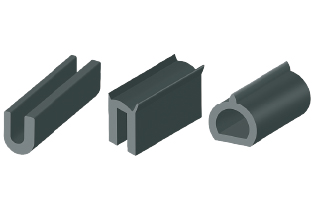

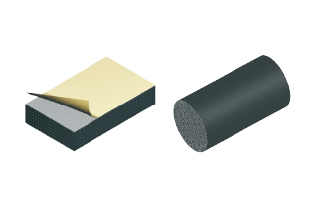

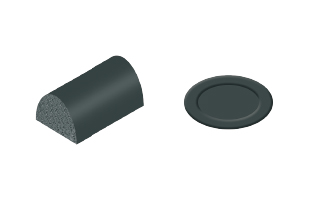

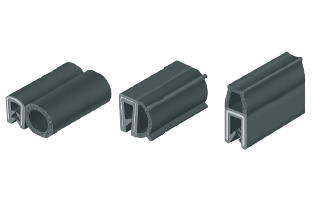

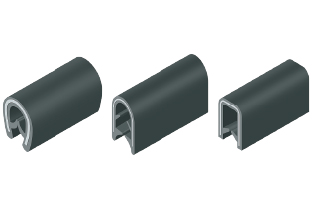

In sheet metal processing, the material thickness also plays an important roal in final cutting quality.Cutting range of stainless steel is 0.5-12mm;The cutting range of galvanized sheet SECC, hot-dip galvanized sheet SGCC, aluminum sheet, copper sheet and other materials is generally within 0.5-8mm. Understanding the cutting thickness of different materials is helpful for us to process better products. Below are some laser cutting metal parts:

Yantai Tanja precision machinery co., Ltd. is a professional industrial hardware factory integrating r&d and processing.Professional in designing kinds of stainless steel products and industrial hardware products, This time,in order to adapt the small quantity customized metal parts,we invest near 2 million yuan to buy this advanced equipment, we belive this will provide more efficient and accurate supply service for customer.provide customer with a full range of hardware solutions.

Sincerely welcome everyone come to our factory for further cooperation.

Tanjia one-stop purchasing platform Copyright © 2018 Adobe Systems Incorporated. All rights reserved.

Please select the language

Please select the language

m@tanja.com.cn

m@tanja.com.cn